| 原理 | 离心式 |

|---|---|

| 执行质量标准 | 企业标准 |

| 产地 | 江苏 |

| 认证 | ISO9001:2008 |

| 适用范围 | 烟气脱硫(石灰石石膏湿法脱硫、双碱法脱硫、循环流化床脱硫、海水脱硫和氨法脱硫等) |

| 过流部件材料 | 双相不锈钢(牌号:2205;2507;2605;Cr30A;CD4MCu) |

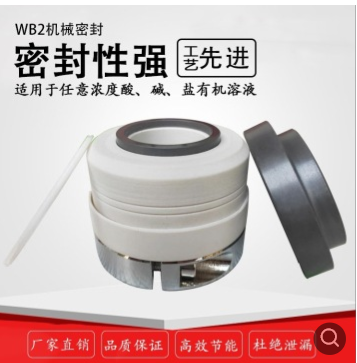

| 机械密封材质 | 无压烧结碳化硅 |

| 材质 | 根据介质而定 |

| 电压 | 380V/6KV/10KV |

| 工作温度 | -20℃~+150℃ |

| 功率 | 160 |

| 级数 | 单级 |

| 流量 | 1.6-3000m3/h |

| 驱动方式 | 电动 |

| 输送介质 | 石灰浆液 |

| 吸入口径 | DN25-DN500mm |

| 性能 | 不阻塞,耐腐蚀,耐磨,无泄露 |

| 扬程 | 5m-125m |

| 用途 | 脱硫浆液循环 |

| 执行标准 | 国标 |

| 转速 | 980 |

| 泵轴位置 | 卧式 |

| 叶轮结构 | 半开式叶轮 |

| 叶轮吸入方式 | 单吸式 |

| 品牌 | 亚梅 |

| 型号 | TLB |

产品详情

产品介绍

一、概述

TLB系列脱硫泵是我公司引进国外先进技术,结合国内脱硫行业的实际情况研制而成的一种新型、高效、单级单吸卧式离心泵。

主要优点:适用范围广

密封寿命长

耐磨、耐腐、无堵塞

适用行业:烟气脱硫(石灰石/石膏湿法脱硫、双碱法脱硫、循环流化床脱硫、海水脱硫和氨法脱硫等)

适用温度:-20℃~+150℃

适用介质:含固量≤40%的任意浓度的酸、碱、盐,特别是石灰浆液、泥浆液、煤渣液、矿渣液、废酸、污水等(颗粒硬质软质度不限)。

性能参数:口径 DN25-DN500mm

流量 1.6m3/h-3000m3/h

扬程 5m-125m

过流部件材料:双相不锈钢(牌号:2205;2507;2605;Cr30A;CD4MCu)

机械密封材质:无压烧结碳化硅。

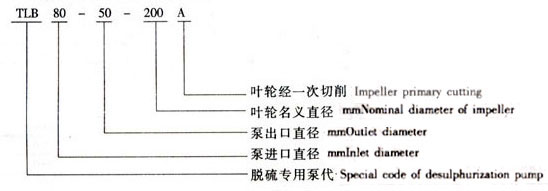

型号意义说明

二、性能参数

表(1)

| 泵型号 | 流量 | 扬程 | 效率 efficiency | 必需汽蚀余量 | 配用功率 | 额定转速 |

| TLB25-25-125 | 3.2 | 20 | 53 | 2 | 1.1 | 2900 |

| 1.6 | 5 | 45 | 2 | 0.55 | 1450 | |

| TLB25-25-160 | 3.2 | 32 | 46 | 2 | 2.2 | 2900 |

| 1.6 | 8 | 40 | 2 | 0.55 | 1450 | |

| TLB25-25-200 | 3.2 | 50 | 38 | 2 | 4 | 2900 |

| 1.6 | 12.5 | 33 | 2 | 0.75 | 1450 | |

| TLB25-25-250 | 3.2 | 80 | 33 | 2 | 5.5 | 2900 |

| 1.6 | 20 | 27 | 2 | 1.5 | 1450 | |

| TLB40-32-125 | 6.3 | 20 | 52 | 2 | 2.2 | 2900 |

| 3.2 | 5 | 46 | 2 | 0.55 | 1450 | |

| TLB40-32-160 | 6.3 | 32 | 47 | 2 | 3 | 2900 |

| 3.2 | 8 | 42 | 2 | 0.75 | 1450 | |

| TLB40-32-200 | 6.3 | 50 | 38 | 2 | 5.5 | 2900 |

| 3.2 | 12.5 | 38 | 2 | 0.75 | 1450 | |

| TLB40-32-250 | 6.3 | 80 | 32 | 2 | 7.5 | 2900 |

| 3.2 | 20 | 35 | 2 | 1.5 | 1450 | |

| TLB50-32-125 | 12.5 | 20 | 51 | 2 | 3 | 2900 |

| 6.3 | 5 | 45 | 2 | 0.55 | 1450 | |

| TLB50-32-160 | 12.5 | 32 | 46 | 2 | 4 | 2900 |

| 6.3 | 8 | 40 | 2 | 0.75 | 1450 | |

| TLB50-32-200 | 12.5 | 50 | 39 | 2 | 7.5 | 2900 |

| 6.3 | 12.5 | 33 | 2 | 1.1 | 1450 | |

| TLB50-32-250 | 12.5 | 80 | 33 | 2 | 15 | 2900 |

| 6.3 | 20 | 27 | 2 | 2.2 | 1450 | |

| TLB65-50-125 | 25 | 20 | 62 | 2 | 3 | 2900 |

| 12.5 | 5 | 55 | 2 | 0.55 | 1450 | |

| TLB65-50-160 | 25 | 32 | 57 | 2 | 5.5 | 2900 |

| 12.5 | 8 | 51 | 2 | 1.1 | 1450 | |

| TLB65-40-200 | 25 | 50 | 52 | 2 | 11 | 2900 |

| 12.5 | 12.5 | 46 | 2 | 1.5 | 1450 | |

| TLB65-40-250 | 25 | 80 | 46 | 2 | 18.5 | 2900 |

| 12.5 | 20 | 39 | 2 | 3 | 1450 | |

| TLB65-40-315 | 25 | 125 | 39 | 2 | 30 | 2900 |

| 12.5 | 32 | 33 | 2 | 5.5 | 1450 | |

| TLB80-65-125 | 50 | 20 | 69 | 2 | 5.5 | 2900 |

| 25 | 5 | 64 | 2 | 1.1 | 1450 | |

| TLB80-65-160 | 50 | 32 | 67 | 2 | 11 | 2900 |

| 25 | 8 | 62 | 2 | 1.5 | 1450 |

表(2)

| 泵型号 | 流量 | 扬程 | 效率 efficiency | 必需汽蚀余量 | 配用功率 | 额定转速 |

| TLB80-50-200 | 50 | 50 | 63 | 2 | 15 | 2900 |

| 25 | 12.5 | 57 | 2 | 2.2 | 1450 | |

| TLB80-50-250 | 50 | 80 | 57 | 2 | 30 | 2900 |

| 25 | 20 | 53 | 2 | 4 | 1450 | |

| TLB80-50-315 | 50 | 125 | 48 | 2 | 45 | 2900 |

| 25 | 32 | 43 | 2 | 7.5 | 1450 | |

| TLB100-80-125 | 100 | 20 | 77 | 4.3 | 11 | 2900 |

| 50 | 5 | 73 | 3 | 1.5 | 1450 | |

| TLB100-80-160 | 100 | 32 | 73 | 4.3 | 15 | 2900 |

| 50 | 8 | 72 | 3 | 3 | 1450 | |

| TLB100-65-200 | 100 | 50 | 72 | 4.3 | 30 | 2900 |

| 50 | 12.5 | 68 | 3 | 4 | 1450 | |

| TLB100-65-250 | 100 | 80 | 68 | 4.3 | 55 | 2900 |

| 50 | 20 | 65 | 3 | 5.5 | 1450 | |

| TLB100-65-315 | 50 | 32 | 58 | 3 | 11 | 1450 |

| TLB125-100-200 | 200 | 50 | 77 | 4.3 | 45 | 2900 |

| 100 | 12.5 | 72 | 3 | 7.5 | 1450 | |

| 67 | 6 | 71 | 2.5 | 4 | 980 | |

| TLB125-100-250 | 200 | 80 | 75 | 4.3 | 75 | 2900 |

| 100 | 20 | 72 | 2.3 | 11 | 1450 | |

| 67 | 9 | 71 | 2.5 | 5.5 | 980 | |

| TLB125-100-315 | 100 | 32 | 68 | 2.5 | 18.5 | 1450 |

| 67 | 15 | 67 | 2.5 | 7.5 | 980 | |

| TLB125-100-400 | 100 | 50 | 60 | 2.5 | 30 | 1450 |

| 67 | 23 | 59 | 2.5 | 11 | 980 | |

| TLB150-125-250 | 200 | 20 | 77 | 2.8 | 18.5 | 1450 |

| 135 | 9 | 76 | 2.5 | 7.5 | 980 | |

| TLB150-125-315 | 200 | 32 | 75 | 2.8 | 30 | 1450 |

| 135 | 15 | 74 | 2.5 | 11 | 980 | |

| TLB150-125-400 | 200 | 50 | 70 | 2.5 | 45 | 1450 |

| 135 | 23 | 69 | 2.5 | 18.5 | 980 | |

| TLB200-150-250 | 400 | 20 | 81 | 4 | 37 | 1450 |

| 270 | 10 | 80 | 2.8 | 11 | 980 | |

| TLB200-150-315 | 400 | 32 | 79 | 3.5 | 55 | 1450 |

| 270 | 15 | 79 | 2.8 | 18.5 | 980 | |

| TLB200-150-400 | 400 | 50 | 78 | 3.5 | 90 | 1450 |

| 270 | 23 | 78 | 2.8 | 30 | 980 | |

| TLB200-150-500 | 400 | 80 | 75 | 3.5 | 160 | 1450 |

| 270 | 36 | 75 | 2.8 | 55 | 980 |

表(3)

| 泵型号 | 流量 | 扬程 | 效率 efficiency | 必需汽蚀余量 | 配用功率 | 额定转速 |

| TLB250-200-400 | 400 | 20 | 82 | 3 | 45 | 980 |

| 306 | 12 | 81 | 2.8 | 30 | 750 | |

| 600 | 40 | 85 | 3.5 | 132 | 1450 | |

| TLB250-200-500 | 400 | 32 | 79 | 3 | 75 | 980 |

| 306 | 18 | 78 | 2.8 | 37 | 750 | |

| 600 | 70 | 84 | 3.5 | 160 | 1450 | |

| TLB250-200-600 | 400 | 50 | 75 | 3 | 110 | 980 |

| 306 | 29 | 74 | 2.8 | 55 | 750 | |

| 600 | 100 | 80 | 3.5 | 315 | 1450 | |

| TLB300-250-400 | 800 | 20 | 83 | 3.5 | 90 | 980 |

| 610 | 12 | 82 | 3 | 45 | 750 | |

| 480 | 7 | 80 | 3 | 22 | 590 | |

| 1200 | 40 | 85 | 3.8 | 280 | 1450 | |

| TLB300-250-500 | 800 | 32 | 82 | 3.5 | 132 | 980 |

| 610 | 18 | 81 | 3 | 55 | 750 | |

| 480 | 11 | 79 | 3 | 30 | 590 | |

| 1200 | 70 | 83 | 3.8 | 315 | 1450 | |

| TLB300-250-600 | 800 | 50 | 79 | 3.5 | 200 | 980 |

| 610 | 29 | 78 | 3 | 90 | 750 | |

| 480 | 18 | 76 | 3 | 45 | 590 | |

| TLB350-300-450 | 1500 | 20 | 86 | 3.5 | 132 | 980 |

| 1140 | 12 | 85 | 3 | 75 | 750 | |

| 900 | 7 | 84 | 3 | 37 | 590 | |

| TLB350-300-550 | 1500 | 32 | 85 | 3.5 | 200 | 980 |

| 1140 | 18 | 84 | 3 | 110 | 750 | |

| 900 | 11 | 83 | 3 | 55 | 590 | |

| TLB350-300-650 | 1500 | 50 | 83 | 3.5 | 315 | 980 |

| 1140 | 29 | 82 | 3 | 160 | 750 | |

| 900 | 18 | 81 | 3 | 75 | 590 | |

| TLB400-350-450 | 2000 | 20 | 87 | 3.5 | 200 | 980 |

| 1500 | 12 | 86 | 3 | 110 | 750 | |

| 1200 | 8 | 85 | 3 | 45 | 590 | |

| TLB400-350-550 | 2000 | 32 | 86 | 3.5 | 280 | 980 |

| 1500 | 19 | 85 | 3 | 132 | 750 | |

| 1200 | 12 | 84 | 3 | 55 | 590 | |

| TLB400-350-650 | 2000 | 50 | 87 | 4 | 450 | 750 |

| 1500 | 32 | 86 | 3.8 | 200 | 590 | |

| 1300 | 20 | 85 | 3.8 | 132 | 500 | |

| TLB450-400-500 | 2500 | 20 | 87 | 4 | 250 | 980 |

| 1900 | 12 | 86 | 3.8 | 110 | 750 | |

| 1500 | 8 | 85 | 3.8 | 55 | 590 | |

| TLB450-400-600 | 2500 | 32 | 88 | 4 | 355 | 980 |

| 1900 | 19 | 87 | 3.8 | 160 | 750 | |

| 1500 | 12 | 86 | 3.8 | 110 | 590 | |

| TLB450-400-700 | 2500 | 50 | 87 | 4 | 560 | 750 |

| 2000 | 32 | 86 | 3.8 | 280 | 590 | |

| 1700 | 20 | 85 | 3.8 | 160 | 500 | |

| TLB500-450-600 | 3000 | 20 | 88 | 4 | 250 | 750 |

| 2360 | 12 | 87 | 3.8 | 132 | 590 | |

| 2000 | 8 | 86 | 3 | 75 | 500 | |

| TLB500-450-700 | 3000 | 32 | 87 | 4 | 400 | 750 |

| 2360 | 20 | 86 | 3.8 | 250 | 590 | |

| 2000 | 14 | 85 | 2 | 132 | 500 | |

| TLB500-450-800 | 3000 | 50 | 85 | 4 | 630 | 750 |

| 2360 | 30 | 84 | 3.8 | 315 | 590 | |

| 2000 | 21 | 83 | 3 | 200 | 500 |

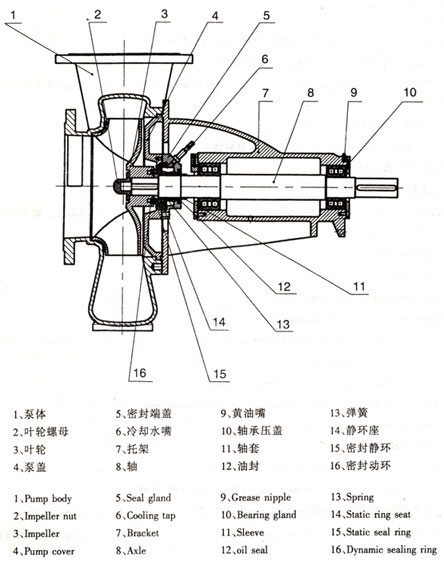

三、TLB系列脱硫泵结构图